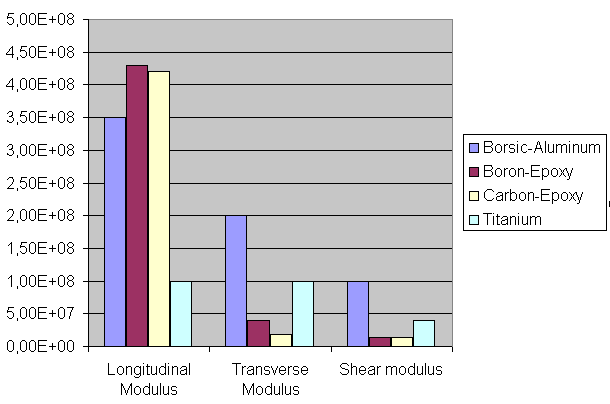

1. METAL MATRIX COMPOSITES1.1. GENERAL PROPERTIESThe metal matrix composites have various advantages over other types of composites. Such as;The high strength values of metal alloys, compared to structural ceramics or organic materials, which can be utilized in composite materials, make them attractive. This high strength is mostly important with respect to composite properties at a direction different from the reinforcement direction. Properties such as transverse strength, torsional strength and interlaminar shear strength are examples of matrix strength controlled properties. The high moduli of metal alloys compared to those of organic materials are particularly significant in high modulus composites. Figure below shows a comparison of several fiber-reinforced composite materials on the base of specific modulus (in inches).

Fig. 1.1. The high toughness and impact properties of metal alloys are very important, since the reinforcement is generally a linear elastic material and does not have good impact properties. Ductile metal matrix alloys such as aluminum, titanium or nickel-chromium alloys undergo energy-absorbing plastic deformation under impact, which is a desirable property for dynamic applications. The ductile metal matrix gives also improved fracture toughness. The comparably low thermal sensitivity of metal matrices enhances their uses in high-modulus structural composites. Other organic matrix materials are quite sensitive to temperature changes. They are more resistant to thermal shocks the than ceramic matrices are. At elevated temperatures, not only do they tend to soften but also their resistance to oxidation, corrosion and erosion drops off significantly. The metal matrices are generally less sensitive to surface flaws than ceramics or organic resins so their surfaces are more durable. The organic resins are more sensitive to small cracks because of various reasons such as low hardness and strength, moisture sensitivity, tendency of porosity, sensitivity to moderate temperature oxidation and ultraviolet radiation. Another advantage of metal matrix alloys is their high thermal and electrical conductivity, which permits the diffusion and elimination of high thermal and electrical concentrations. Problems such as lightning strikes and hot-gas impingement are less sever if the impacting energy can be conducted away more rapidly. Another important asset of metal matrices is their excellent reproducibility of their metal properties. This property is important not only for matrix alloy properties but also the bonding and the interfacial properties. Another important advantage of metal matrix alloys is the availability of an excellent technological background of their present use in the design of engineering structures, manufacturing techniques and a comprehensive information on service durability. Although metal matrix composites have a lot of advantages, they have some important disadvantages. One of the most important disadvantages is that the metal matrices are poor in chemical and mechanical compatibility with the reinforcements. In other words, the chemical inertness of the reinforcement (usually a fiber) at modest resin-fabrication temperatures and large elastic compliance of the matrix are the chemical and mechanical incompatibility problems. Another reason of preference of resin-matrix composites is that the metal matrix composites are harder to fabricate then the resin-matrix composites. To summarize; there are a lot of advantages of metal matrix composites over the other types but yet it has also some disadvantages too; so careful consideration must be given before preferring the metal matrices to the other types of composite materials.

The three-dimensional reinforcement can lead to isotropic properties, since the material is symmetrical across the three orthogonal planes. Strength of the particulate composites normally depends on the diameter of the particles, interparticle spacing and volume fraction of the reinforcement. Matrix properties, including the work-hardening coefficient, which increases the effectiveness of the reinforcement constraint, are also important.

The elastic constants of a structural lamellar composite have been predicted by laminate theory. In either of the directions of the reinforcing plates is given by the rule of mixture: EC = ERVR + EMVM where ER, EM and EC are the elastic moduli of the reinforcement, matrix and composite respectively, and V refers to the volume fraction. The strength of laminated composite materials relate more closely to the properties of the bulk reinforcement. Since the reinforcing lamellae can have two dimensions that are comparable in size to the structural part, flaws in the reinforcement can nucleate cracks of lengths to that of the part. Since the most important reinforcing materials are brittle in nature, their strength is related to the population of their flaw density and intensity.

The reinforcements of strength in all directions of the plane is a good advantage but their strength, elongation and ductility is lower than the fiber reinforced composites, since the corresponding values of films are lower than the values for fibers.

Fig. 1.2. Schematic curve showing the stress-strain behavior of a metal-matrix composite: (I) fiber elastic, matrix elastic; (II) fiber elastic, matrix plastic; (III) fiber plastic, matrix plastic; (IV) fiber fractured. When the metal-matrix composite with continuous uniaxially aligned fibers is stressed parallel to the fibers, four stages of stress-strain behavior is observed. In first stage, both the fiber and the matrix deforms elastically. The elastic modulus has been found to be EC = EFVF + EMVM where V stands for volume fraction of the matrix M and the fiber F. The second stage comprises the region in which the fiber is extending elastically and the matrix is extending plastically. Since the fiber is usually in high volume fraction and has a considerably higher elastic modulus than the matrix, E2 is nearly equal to E1. The modulus of the composite would be the addition of the slopes on the stress-strain curve of the two phases times their volume fractions: E11 = EFVF + (dsM/deM) where dsM/deM is the effective strain-hardening coefficient of the matrix phase, which is normally much less then the modulus of the fiber and can be neglected. Therefore, the modulus of the elastic-plastic portion of the stress-strain curve frequently can be given as E11 = EFVF The third stage is observed when both fiber and matrix can undergo plastic deformation and includes normal plastic extension of the two phases. This deformation mode may deviate from the performance of the constituents alone with respect to necking or other inhomogeneous plastic flow. Forth stage in the stress-strain performance of the composite includes the fracturing of the high strength fibers. During this stage, the matrix transfers load from broken fiber ends to unbroken segments and flows around the opening pores or cracks. Fracture of the composite normally terminates the forth stage. The transverse or the shear properties of fiber-reinforced composite materials are considerably more influenced by the matrix behavior than the longitudinal properties are.

Filamentary reinforcement has been found to make possible the most effective reinforcement of metal matrix systems. These filaments used with three classes of engineering metals: low temperature alloys such as aluminum alloys; intermediate temperature alloys such as titanium and high temperature alloys such as nickel-based superalloys or columbium alloys. Although the requirements of reinforcements change as the matrix alloy is changed; there are some common properties such as:

Rocket wire (steel), molybdenum and tungsten: high strength, ductility, excellent high temperature creep, but low modulus -to-density ratios

Problems vary with the particular matrix-fiber combination being considered but at least these three must always be kept in mind:

Powder Metallurgy: The powder metallurgy technique usually employs whiskers or cut fibers of the reinforcing materials. These are nixed with the matrix powder and then pressed to consolidate the matrix. This may or may not be followed by sintering to improve matrix density. A major problem when using powder metallurgy is the elimination of porosity. There is also difficulty in obtaining alignment of the reinforcing material.

Fig. 1.3. Flowsheet for production of Composite of Titanium Reinforced with Molybdenum Fibers

Fig. 1.4. Microstructure of 15 Volume Percent Alumina in Beryllium (400X) )Courtesy of Aerospace Corp.) Pneumatic Impaction: Pneumatic impaction can be considered as a variation of powder metallurgy since a powdered matrix is employed. The mixture of powder and reinforcing fiber is prepared and high unit pressure is applied by means of an impacter or a Dynapak machine. Plasma Spray Deposition of Matrix: This is a combination of a powder process and liquid process and also involves hot pressing. A layer of fibers is laid up on a rotating mandrel, the metal is deposited on the fibers by plasma spraying, a second layer of fibers is put on, and the operations are repeated until the desired thickness and the number of layers is attained. Vapor Deposition: Vapor deposition is a process where the reinforcement, particularly whiskers are coated by the matrix material from the deposition of its compounds. Extrusion process is finally employed for orienting the whiskers parallel to the extrusion axis.

Fig. 1.5. Heavy Vapor-plated SiC Whiskers, 1 to 5m, Bottom Surface of Mat (50X) (Courtesy of Melpar Inc.) Electroforming: This process is especially used to prepare composites of boron in aluminum matrix. A continuous boron filament is on a mandrel is immersed in a solution. Aluminum is continuously plated from this bath as the filament is wound. Vacuum Infiltration of Fibers by Molten Metal: This is a method for preparations of small specimens of composites containing metallic or ceramic fibers in aluminum, magnesium, silver, copper and alloy matrices whose melting points are quite low. The composites were formed under vacuum by casting the matrix around the coated filaments.

Fig. 1.6. Cross-section of Boron Filament-Aluminum Matrix Samples Made by Liquid Infiltration (35X) (Courtesy of AVCO Corp.) Fusion casting: There are two approaches of making a composite, which can be considered as a casting. In first method, a continuous reinforcing filament is fed through a pot of molten metal.

Fig. 1.7. Furnace for Application of Aluminum Coating to Steel Wire The other way is the introduction of molten metal into, around and through mats or bundles of fibers or whiskers.

Fig. 1.8. Silicon Carbide Whiskers in M-45 Aluminum Alloy (150X) Unidirectional Solidification of Eutectic Alloy: Another method of composite formation is growth from a melt at certain temperatures and for some time ranges.

Co-extrusion: Co-extrusion is a method that has been employed for the incorporation of continuous wires or filaments to matrix. Since the matrix is worked by extrusion, it will contribute appreciable strength to the composite.

Fig. 1.11. Design of Extrusion Tooling for Producing Composite Wire

Fig. 1.12. Extruded Aluminum-Steel Wire Rolling: Hot or cold rolling can be employed to consolidate coated continuous fibers or to introduce continuous fibers or wires in matrix metal strips.

Fig. 1.13. Steel Wires Rolled into Aluminum Strip (100X) Diffusion Bonding: In this method, alternate layers of matrix foil and properly spaced and oriented reinforcing fibers are laid down until the necessary amount of material for the desired final thickness is assembled. Then, by a combination of heat, pressure and time in a vacuum, the matrix is caused to flow around the fibers and bond to the next layer of matrix and at the same time grip the reinforcing fiber very tightly.

Fig. 1.14. Boron-Aluminum Composite, 44 Volume Percent Boron Fiber, 0.004 Diameter (100X)

|

||||

|

Contents:

|